Process and Parameter Intensification for Pilot Scale Demonstration of 2,3-Butanediol (BDO) Biosynthesis (PILOT-DIOL)

- Project lead

- Vinod Kumar

- Institute

- Cranfield University

Summary:

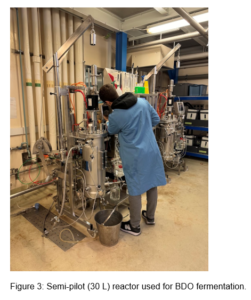

Currently, the global chemicals sector emits two gigatonnes of greenhouse gases every year. One reason for this is that the bulk of small molecules are produced from fossil fuels, but there is a strong drive to use bio-derived chemicals wherever possible, as this is an essential step forward in reducing the industry’s carbon footprint. As a result, we have recognised a substantial possibility to valorise bread waste the abundant non-edible renewable source available into 2/3-butanediol (BDO), a critical molecue utilised in chemical, pharmaceutical, and agrochemical sectors. Microbial synthesis of BDO is an environmentally friendly process with minimal dependence on the natural resources and our preliminary laboratory exploration provided us the confidence of commercial feasibility, but for innovation to be recognised the translation of the process into higher scales meeting the market demand is of higher significance. The scaling of bioprocess consists of transferring smaller volume bench scale experiments into larger semi-pilot or pre-commercial scale volumes for the product generation. The scale-up involves various critical parameters and serious economic and technical implications if not designed through proper expertise. The project PILOT-DIOL utilizes non-edible bread waste (BW) as feedstock, where it is converted into fermentable sugars through enzymatic hydrolysis and further Enterobaster ludwigii, a potent non-pathogenic bacterial strain converts there sugars into BDO. The project PILOT-DIOL de-risks the various physical, chemical and technical limitations in scale-up process with validations in 300 L bioreactor. Further the project outcomes will be communicated by C-Source Renewables Ltd. and Cranfield University through various social platforms to reach wide audience.

Aims:

The aim of the project was to reduce industrial bread waste by optimizing enzymatic hydrolysis conditions to maximize glucose yield, and subsequently produce BDO through fermentation. The project sought to scale up the process from laboratory to semi-pilot scale, promoting sustainable waste management practices, reducing environmental impact, and enhancing economic viability by transforming food waste into valuable bio-based chemicals. Additionally, it aimed to generate technical insights for future waste valorization and bioprocess optimization.

Outcomes:

The project successfully demonstrated the conversion of industrial bread waste into valuable bio-based chemicals, primarily glucose and BDO, using optimized enzymatic hydrolysis and fermentation processes. Utilizing a Central Composite Design (CCD), the team identified the optimal conditions for glucose production, which included a solid loading of 40%, enzyme loading of 0.4 µg/g, and incubation at 55°C for 48 hours. These conditions resulted in glucose yields ranging from 40.85 g/L to 234.9 g/L.

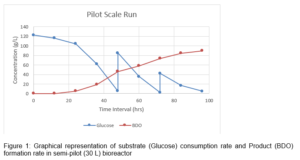

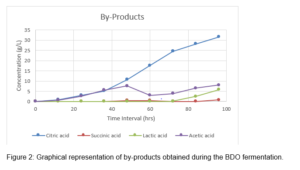

Validation experiments conducted in triplicate at a larger scale confirmed the accuracy of the optimization model, with minimal deviation from predicted glucose outputs. The project also addressed the challenge of high viscosity at 50% solid loading, emphasizing the need for effective mixing during scale-up. Subsequent scale-up experiments involving a 16 kg batch demonstrated the feasibility of the process on an industrial scale, achieving consistent glucose production and successful fermentation to BDO. The fermentation process achieved 100% substrate utilization within 96 hours, reaching a maximum BDO concentration of 89.5 g/L.

These outcomes highlight significant environmental and economic benefits. The project showcased a sustainable method for managing bread waste, transforming it into valuable bio-based chemicals and reducing the environmental impact associated with food waste disposal. The economic viability was also demonstrated, with potential cost savings from reduced waste disposal and revenue from bio-based product sales. Furthermore, the project provided valuable technical insights for future research and industrial applications, supporting the development of efficient waste-to-value bioprocesses and contributing to the advancement of the circular economy.

Impact:

The project significantly reduced bread waste by converting it into valuable chemicals, demonstrating sustainable waste management, economic viability, and environmental benefits. It provided a scalable model for waste-to-value bioprocesses, contributing to the circular economy and offering technical insights for future industrial applications.

Academic partner: Vinod Kumar, Cranfield University

Industrial partner: Rylan Cox, C-Source Renewables Limited