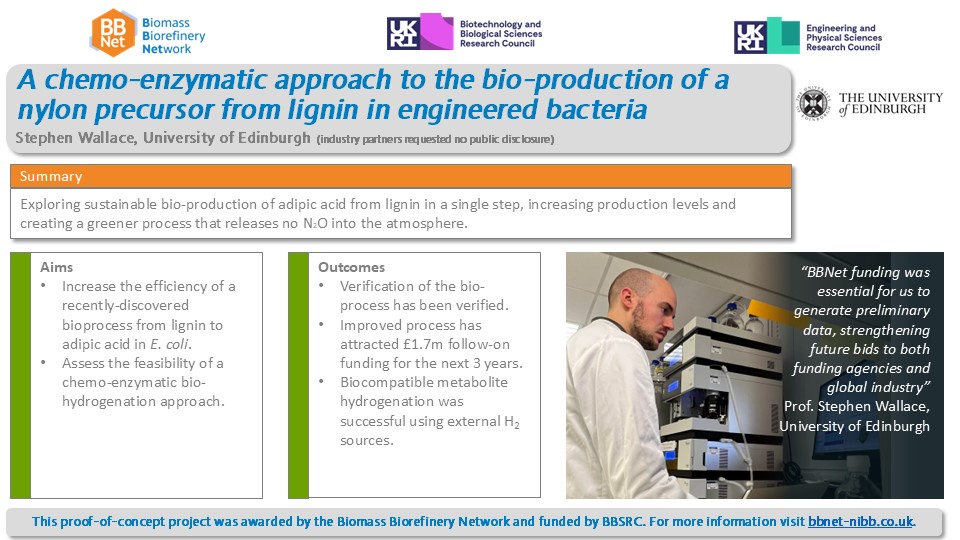

A chemo-enzymatic approach to the bio-production of a nylon precursor from lignin in engineered bacteria

- Project lead

- Stephen Wallace

- Institute

- University of Edinburgh

Summary:

Adipic acid is an important industrial chemical that is used primarily for the manufacture of nylon fabric. Over three million tonnes of adipic acid are manufactured each year worldwide via an industrial process that currently relies on diminishing fossil fuels and also emits unacceptable volumes of greenhouse gas into the atmosphere. In fact, in 2015 adipic acid was responsible for 10% of all human-associated nitrous oxide emissions worldwide (a greenhouse gas 300-times more damaging that CO2).

Although engineering biology routes to adipic acid are being actively investigated, the industrial use of this process is hindered by a lack of efficient enzymes. As such, current bioprocesses rely on the time-consuming and expensive extraction of intermediates and their downstream chemical processing to adipic acid in a separate step. This hurdle is one of the main barriers to the industrial implementation of a sustainable bioprocess to adipic acid from renewable feedstocks.

In this study, we will explore the use of biocompatible chemical reactions to process intermediates to adipic acid in the presence of living bacteria. This will enable the complete production of adipic acid from lignin in a single step and increase overall production levels, whilst creating a greener overall IB process that releases no N2O into the atmosphere. We will focus on use of the feedstock lignin – a by-product of the agricultural and paper-milling industries that is currently incinerated (generating CO2) and as such is widely considered to be one of the largest untapped sources of carbon on Earth.

Aims:

To increase the efficiency of a recently-discovered bioprocess from lignin to adipic acid in E. coli and to assess the feasibility of a chemo-enzymatic bio-hydrogenation approach.

Outcomes:

The process has been verified, improved and attracted £1.7m follow-on funding for the next 3 years. Biocompatible metabolite hydrogenation was successful using external H2 sources.

Impact:

The project team has grown, additional industrial partners have joined and the pathway/system is now being further intensified with the aim of assessment at pilot scale in 2025/26

Academic partners: Prof Stephen Wallace, University of Edinburgh

Industrial partners: Industry partners have requested no public disclosure