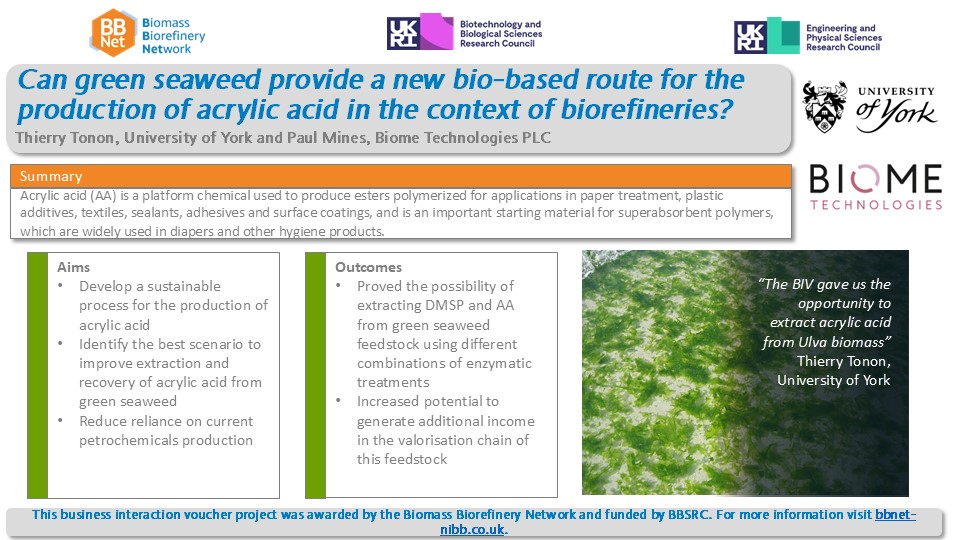

Can green seaweed provide a new bio-based route for the production of acrylic acid in the context of biorefineries?

- Project lead

- Thierry Tonon

- Institute

- University of York

Summary:

Acrylic acid is a platform chemical used to produce esters which are polymerized for applications in paper treatment, plastic additives, textiles, sealants, adhesives and surface coatings. It is also an important starting material for superabsorbent polymers, which are widely used in diapers and other hygiene products. The market value of acrylate is expected to reach $19b by 2020. Current production relies on a petrochemical process, however, due to unstable oil prices and environmental concerns, industry players have invested in R&D for bio-based acrylate production. Among the routes tested so far, fermentation processes of sugars to produce lactic acid or 3-hydroxypropionic acid, which are then dehydrated to acrylic acid, have been developed recently.

However, none of them has yet reached the commercial stage. Therefore, there is scope to identify new routes for bio-production of acrylic acid, including extracting this compound from green seaweeds.

Aims:

Current production relies on petrochemistry, and a sustainable process for the production of AA is needed. We have assessed the extraction of AA and of its precursor dimethylsulfoniopropionate (DMSP) from the green seaweed Ulva sp..

Outcomes:

We have showed the possibility of extracting DMSP and AA from green seaweed feedstock using different combinations of enzymatic treatments. Amounts of DMSP and AA extracted ranged between 0.30-0.45 % and 0.23-0.82 % of the biomass dry weight at the end of the processes. Both compounds are highly soluble and were mostly extracted after mixing the biomass with water, and after one enzymatic step. These results pave the way for future comparison of extraction of AA and DMSP with other well established biomass treatments such as microwave and chemical processes under on acid or and alkaline condition.

Impact:

Based on our results, extraction of AA and DMSP should be given consideration when implementing biorefinery concepts for bloom forming and farmed Ulva sp. biomass. This would provide a more sustainable source of AA, and generate additional income in the valorisation chain of this feedstock.

Academic Partner: Thierry Tonon, University of York

Industrial Partner: Paul Mines, Biome Technologies Plc